- The material of high transparent plexiglass vacuum chamber is firm and durable.

- Touch screen display, microcomputer control, human-computer interface, convenient and fast

The instrument can automatically store data, which is convenient for users to query.

The instrument can automatically store data, which is convenient for users to query.

- Equipped with micro printer to print experimental results quickly

- Independent operation button, alternating operation with touch screen, gives you more operation experience.

- The pressure gauge clearly shows the pressure value

- The pressure regulating valve can control and stabilize the air source pressure, so that the operator can adjust the pressure according to the experimental requirements

- The speed control knob can adjust the air flow speed and inhibit overcharge

One instrument has multiple test modes

Pressure maintaining test, bursting test, anti-theft bottle cap, coarse leakage, rapid leakage, end cap separation, sealing test, internal pressure resistance test, creep test, sectional mode

INSTRUMENT SPECIFICATIONS

| measuring range |

0~1.25MPa |

| measurement accuracy |

±1% |

| air connection |

Ф8mmPolyurethane tube |

| Machine size |

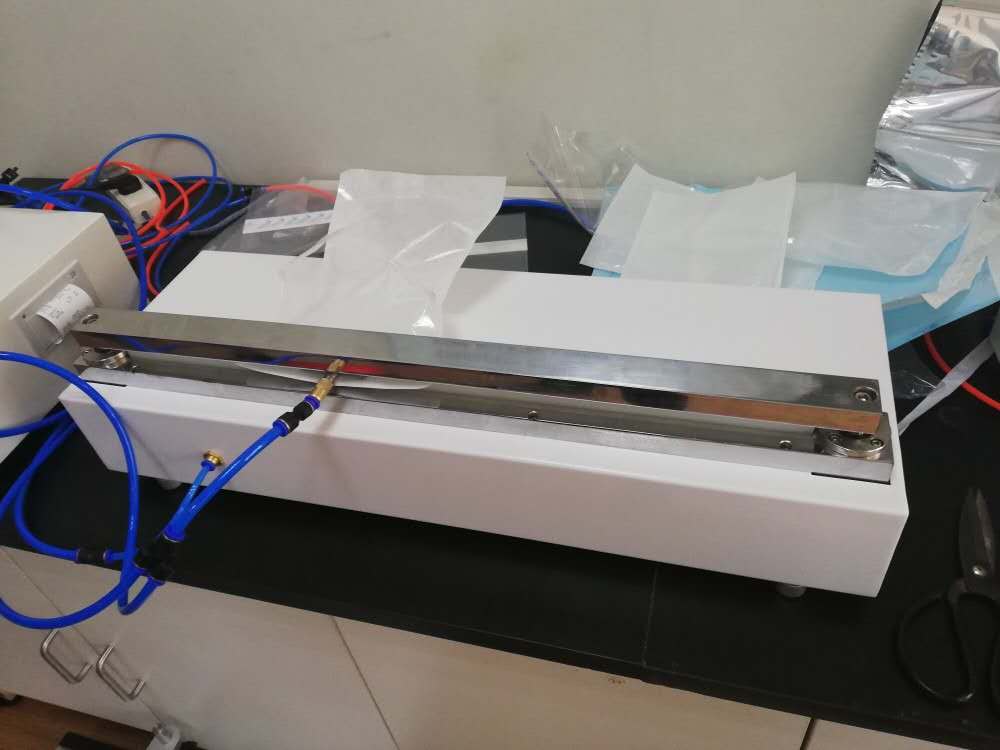

480mm×330×150mm |

| Weight |

18KG |

| Gas pressure |

0.4 MPa~1.3MPa |

| Working power |

220V 50HZ |

Standards

GB10440、GB18454、GB19741、GB8368、YYT0681、YY0285、ASTM F1140、ASTM F2054、ASTM D3078、ISO 11607-1 、 ISO 11607-2 、 GB/T 19633 、 GB/T 17876 、 BB/T 0025 、 QB/T 1871 、 YBB00252005-2015、YBB 00162002-2015

Instrument configuration

Standard:Mainframe, plastic anti-theft bottle cap sealing performance test device, sealing barrel, micro printer Optional: Test accessories (restraint plate test device, open package test device, thick leakage test device, test stand, hose sealing performance test device, end cover release force device, quick leakage device, etc.)